Eoin is a CONFIRM Post-Doctoral researcher based at the University of Limerick

“I love the challenges that arise in research, and the enjoyment I get from solving these challenges. I love figuring things out.”

Tell us a bit about your research...

My research has evolved since my PhD. My PhD research was very much focused on material science, and in particular, the study of special metals called Nickel superalloys. After my PhD I worked in R&D in industry on metal 3D printing, so although there was an element of material science, it was more focused on digital manufacturing.

My current role in Confirm is researching Digital Twin technology. Before I applied for the role, I had never heard of this term “Digital Twin”, however, I’ve seen its use grow substantially in the past 2 years. Essentially, a digital twin is a virtual / digital / cyber representation of something physical. So it’s just like a 3D computer model of something physical, but with a twist. The difference between a digital twin and a digital model is that a digital twin changes as the real world changes, while a digital model does not. That means that a digital twin needs a connection with the real world, so as the real world changes, the digital twin changes too.

The best example I give when trying to describe what a digital twin is to consider Google Maps. Google Maps is a great example of a digital twin. Google maps is a digital representation of the road network in Ireland. So although Google Maps may appear to be a digital model, it is more than that, as it has a connection to the real world. If you open Google Maps on your phone, or PC, and turn on the traffic filter, you will see some of the roads change colour from green to yellow, to orange, to red, or to very dark red. This is real time traffic information that Google Maps gets from smart phones that are stuck in the traffic – meaning Google Maps is connected to the real world! Google Maps also adds value to our lives, as it can save us time by redirecting us away from the traffic hot spots, allowing us to get to our destination quicker!

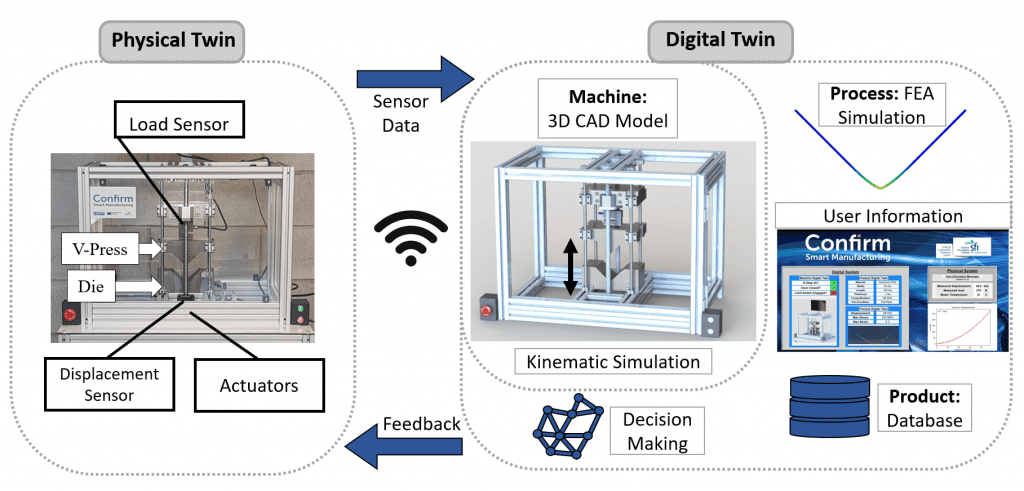

My research involves building similar digital twin systems, but for manufacturing. When something is being made in manufacturing, there is a machine that is doing a job (process) on a product. That means that there should be three parts to a digital twin: the machine digital twin, the product digital twin and the process digital twin. For example, the machine might be drilling a hole, or gluing plastic together, or bending a piece of metal. My research looks at making digital twins of these systems to help improve manufacturing efficiency, speed and reduce costs.

I am currently making a digital twin of a metal bending process. Metal bending is used in in a variety of industries, such as making cars, airplanes, as well as medical equipment. Metal bending can be a complicated process, especially if you’re making a very precise part. When you bend metal, it tends to spring-back (just like when you squish a spring, it bounces back to the original size when unloaded). This makes it very tricky to get right first time, especially because the metal springs back different amounts depending on its geometry and material type. However, with digital twin technology, metal bending can be simulated using computers, which allows us to predict the how much the metal will bend, and compensate for the spring-back. This allows us to figure out the exact process steps before ever going near the bending machine.

As part of my research, I am designing and building a physical bending machine – similar to that found in a factory. I put a bunch of sensors on the machine (like temperature sensors for example), which help me understand what’s happening inside the physical machine. I also made 3D digital models (like those you see in video games) of my machine, as well as computer simulations of my metal bending process, both of which I use as part of my digital twin. One really important area for me is how do I get the information from my sensors into my digital twin, so my model will update in real time as the physical machine operates. Once this communication is established between the physical machine and digital machine, it means that the digital twin is synchronized with the real world. Finally, using this sensor information from the real world and my computer simulated results, my machine can make decisions on the best process parameters to use for bending metal – ensuring I get the best results every time!

What did you study as an Undergraduate?

I was always mechanically-minded growing up. I used to always take McDonald’s toys apart with screwdrivers (back before they changed the screw heads to triangles). I took everything apart to see what was inside and to figure out how it worked. I have one specific memory being in the kitchen at home, and deciding to open up my Game Boy to see how it worked inside. I remember my dad saying to me that if I broke it I wouldn’t be getting another, so I swiftly put down the screwdriver and stepped away from the Game Boy! I was really lucky growing up to have plenty of Lego. It started of with my sisters Duplo sets, then as I got bigger I got normal sized Lego, then as I got bigger again I got Lego technic and Lego Mindstorms. I used to ask Santa for Lego each year, and he didn’t let me down!

Being so mechanically-minded, I knew in secondary school that I wanted to be an engineer, so I decided to put Mechanical Engineering down on my CAO. Being from Dublin, I saw my two options as UCD and Trinity. I put UCD as my number 1, as I liked the campus, and it was much closer to home. I started my undergrad in UCD in 2007, and finished 4 years later as a qualified mechanical engineer in 2011. I met some really great people along my journey, and learned some really useful things. People think that if you do one particular course, such as mechanical engineering, you’re just exposed to mechanical engineering stuff, but over the 4 year course we learned about other areas such as chemistry, electronics, energy systems, and I even took two modules on Exploring the Solar System and Space Science!

What made you decide to go into research?

I’ve always been curious and inquisitive – trying to figure things out. Some times when I find something challenging, I get frustrated, but when I take my time and figure it out, it is really rewarding. It’s a great feeling when you figure something out and understand it, and research is all about that for me. To be honest, during my undergrad, I never really knew what a PhD was. Growing up I didn’t know anybody with a PhD, apart from Ross Geller in the TV show Friends – but that doesn’t really count! In my final year at UCD, I was assisting a PhD student in researching applications for micro and nano-injection moulding. I really enjoyed trying to figure out the topic which was alien to me. Looking through journal papers, which are like experiment reports, was like trying to find clues on the topic. And the more journal papers I read, the more I could piece together, the more things made sense to me. This sparked my interest in pursuing a PhD, which is essentially a research project spaced out over a number of years. At the end of my undergrad, I got the opportunity to apply for funding to study a PhD in the University of Limerick on the repair of superalloy turbines from airplane engines with Lufthansa Technik Turbine Shannon. This sounded like such a cool project to do – I knew it was for me!

I applied for the funding from the Irish Research Council (IRC) for the project in mid-2011, and unfortunately I didn’t get it. I was really disappointed because my proposal missed the cut off by only 1.5%. I didn’t give up though, because the opportunity was too good to miss, and I was so close to the target. There was another identical funding opportunity with the IRC 3 months later, so I tidied up my application and resubmitted it. I got word in late Nov 2011 that I was successful, and I started my PhD in UL in January 2012! So it just goes to show that if you do get knocked back in life, stay determined, because things can work out!

What do you enjoy most about being a Post-Doc?

Since July 2018 I have been working as a post-doc with the Confirm Smart Manufacturing Research Centre. A post-doc (which is short for post-doctoral researcher) is a researcher who has a doctorate, i.e. they have completed a PhD. I graduated with my PhD in 2016, and went to work in industry with Johnson and Johnson in Cork on researching metal 3D printing of human joints for a couple of years. I really enjoyed this work, as I felt that my contributions would help patients who are suffering from arthritis. After 2 full years in Cork, the opportunity to return to UL in the newly-established Confirm Center as a post-doc came up, and I jumped at the chance!

There are many things I enjoy about my current role. I love the challenges that arise in research, and the enjoyment I get from solving these challenges. I love figuring things out. I love teaching, and I have been lucky enough to teach undergraduate students and master students about my research. It’s a very fulfilling role. I like to read journal papers, and I love technical writing. It’s funny, I really disliked English as a subject in school, and didn’t really like reading books at all growing up, but as I’ve gotten older I have found that I love writing technical engineering reports and journal papers. Another thing I like about my role is that I mentor other research students. I help review their work, give them advice on their research, and I get to correct their reports just like a teacher would!

One of the best things about being a researcher in a University is the atmosphere. There is a great buzz about the place all year round. The summer is a bit quieter when the students are gone, but there is a great sense of atmosphere when the students are around.

Do you have any advice for someone who is thinking about a career or research in STEM?

I think if you are curious about the world, and like solving problems, then STEM is a great fit.

If you are an undergrad in STEM, and are considering a PhD but are unsure, then there are a few things to bear in mind. The first thing is that you don’t need to be a genius – you just need determination! I found when I was doing a PhD, and told somebody I was doing a PhD, their natural reaction was “oh you must be a genius!”. Essentially what a PhD boils down to is a long research project, spread out over a couple of years. You don’t need to be Sheldon Cooper from The Big Bang Theory to be able to do a PhD. There’s so much more to be gained from a PhD than just becoming an expert on a very specific topic. You become very good at technically reading, planning, writing and communicating. There is opportunity to travel to conferences in nice locations, and you get the opportunity to teach undergraduate students. And on top of all that you get paid to do it!