What is a Digital Innovation Hub (DIH)?

A digital innovation hub (DIH) is a one-stop-shop that helps enterprises to become more competitive in terms of their business/production systems, processes, products or services using digital technologies. Based upon a competency centre and technology infrastructure they provide access to current knowledge, expertise, and technology to support stakeholders in piloting, testing, and experimenting with digital innovations.

DIHs are regional, multi-partner co-operations with linkages to a variety of service providers inside and outside their region, allowing orchestration and access to services seamlessly to stakeholders.

CONFIRM Digital Innovation Hub (DIH)

CONFIRM DIH is focused on the application of digital innovation across the manufacturing value chain to foster growth and competitiveness in the Irish manufacturing industry and enable Irish based manufacturing companies to compete within the rapidly changing global landscape.

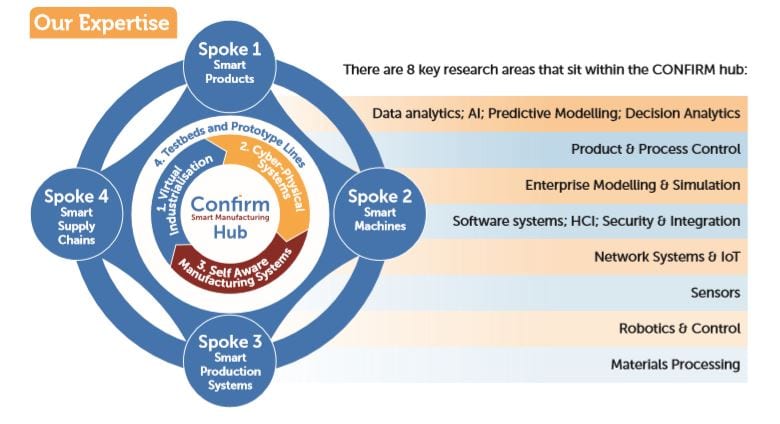

Smart manufacturing involves optimising production systems, developing Smart products, Smart machines, Smart production systems, and Smart supply chains by adding intelligence, enhanced information technology, and IoT. These new technologies will be at the heart of Industry 4.0, the factories of the future, increasing product line adaptability, enabling real-time decision making, shortening supply-chains, and speeding up the development of new innovations to produce higher-quality goods at reduced costs across all industry sectors.

The CONFIRM DIH incorporates a Centre of Excellence with shared research facilities, access to state-of-the-art equipment and a broad ecosystem of stakeholders. CONFIRM DIH offers technology and support services to companies of varying sizes from SME and Mid-Caps to large MNEs. It provides access to knowledge, expertise and training in the smart manufacturing domain. CONFIRM’s solutions, moreover, provide for different customised approaches addressing companies on different innovation stages, from awareness raising and maturity level identification for newcomers to digitization to tailored solutions and services for starter companies, to full systems solutions for advanced companies

CONFIRM is a not-for-profit, national strategic initiative supported by Science Foundation Ireland (SFI), the Irish national foundation for investment in scientific and engineering research. The CONFIRM DIH draws on the expertise of 9 core Irish research performing organisations (RPOs), 16 international collaborations, and numerous industry partners across MNC and SME sectors to deliver cutting-edge research and development projects in the smart manufacturing domain. It provides the skills and services required to place Irish-based industry at the forefront of the smart manufacturing revolution, helping companies of all sizes – ranging from SME to larger organisations – compete globally at the highest level.

The CONFIRM DIH is an open platform to accommodate the diverse digital innovation needs of the manufacturing industry in Ireland and is a driving force in the delivery of technological advances and expertise for a Smart Manufacturing innovation ecosystem.

CONFIRM’s core research activity is in the areas of:

To maximise the impact of our research initiatives, the CONFIRM DIH coordinates R&D and innovation activities:

- Provides communication & outreach to the manufacturing industry,

- Promotes a positive perception of manufacturing in wider society

- Contributes to the development of a skilled human resource pipeline for the manufacturing industry

- Provides a liaison between companies and a network of experts

- Promotes new collaborative multi party national and international research projects to implement digital technologies for Irish based manufacturing companies

Service Examples

Problem

Robotics & Drives are an Irish SME working on the development of a next-generation Human-machine interface for use with an industrial robot system, targeting customer applications in the medical device, pharmaceutical, automotive, food & beverage, plastics and consumer goods sectors. A human–machine interface (HMI) in an industrial robot is system that allows the human operator to control, monitor, collect data, and also program the robot system. Common HMI systems for industrial robots may incorporate a computer screen, pendant consoles, spin buttons, and arm sticks. However, the interface may also go through a chain of devices that on one side convert human-intelligible commands into robot commands and on the other side convert robot feedback into human-understandable information. At the beginning of the chain (close to the human operator) there is a robot control station equipped with a series of human–machine interfaces, at the other end there is a robot controller. Different HMIs are needed to deal with different types of involvement of the human operator. For programming activities, the consolidated HMIs of computer consoles are adequate; for advanced programming involving

interaction with three-dimensional computer models, new user-centered HMI technologies are required that considers usability, safety and utility. Robotics & Drives required an appraisal of state-of-the-art HMI, including augmented reality (AR), hardware and SDK for industrial robots, an experimental evaluation of a prototype HMI system for a customer specific application with an analyses of user Safety considerations.

Solution

CONFIRM researchers at Athlone Institute of Technology (AIT) are working alongside Robotics & Drives staff to develop a prototype HMI system leveraging AR technology, for customer demonstrations and user experience analysis. CONFIRM performed Quality of Experience (QoE) Evaluations of HMIs for operation of remote industrial Robotic Arms to determine the usability factors that contribute to QoE and the utility factors that contribute to QoE.

Key Industry Benefits

Continuing advances in robot HMI technology are a key enabler for human in the loop Industry 4.0 applications. The application of ‘Augmented Reality’ and new AI technologies in the industrial robotics domain will bring new market opportunities for Robot OEM suppliers and robotics and automation specialists such as Robotics & Drives.

Problem

Elastomeric valve seals remain the number one source of contamination in pharmaceutical and other process industries. Unfortunately, there exists significant challenges with real-time prognosis and remaining useful life predictions of these seals. Coupled with this, the pharmaceutical industry faces increasing pressure to adopt new manufacturing methods within legacy plants to reduce manufacturing costs. To meet these demands, manufactures must become more dynamic, agile, and lean with regard to both their production and maintenance scheduling. SCRI-IS Technologies Ltd. is an Irish SME providing end-to-end technical solutions focused on Industry 4.0 enabled asset management technologies to help the process industry achieve these goals.

Solution

CONFIRM researchers at Cork Institute of Technology (CIT) worked alongside SCRI-IS Technologies staff to develop innovative sensing and data acquisition solutions to detect elastomer degradation in situ. Novel data-driven prognostics based on state-of-the-art AI techniques have been developed. In addition, research on the application of state-of-the-art differentially private mechanisms for privacy preserving data aggregation has been conducted to ensure data protection compliance; systems and control theory to improve the accuracy of the data released.

Key Industry Benefits

- The research outputs enable true remaining useful life inferences for elastomeric seals operating within unique process environments

- The research output supports more dynamic, agile, and lean production and maintenance scheduling, helping industry to meet the challenges of pharmaceutical production in the 21st Century

- The research output supports more dynamic, agile, and lean production and maintenance scheduling, helping industry to meet the challenges of pharmaceutical production in the 21st Century

- The research output supports more dynamic, agile, and lean production and maintenance scheduling, helping industry to meet the challenges of pharmaceutical production in the 21st Century

Problem

Croí na Gaillimhe is a small team with big aspirations to help those within the community.

Croí na Gaillimhe means “Heart of Galway” in English and the organisation couldn’t be more aptly named. Croí na Gaillimhe is a charity who offer social, educational and developmental support for people who find themselves isolated or socially or economically excluded. In other words, it is a safe space where people can go to feel welcomed and be involved in activities that allow them to develop new skills and/or meet new people.

Through the CONFIRM network we were made aware that they were keen to leverage our expertise to run a workshop looking at the topic of cyber-security and data management as applied to their own work. A core element of CONFIRM is our Education and Public Engagement (EPE) programme which seeks to raise awareness and increase dialogue between STEM researchers (particularly in the area of Smart Manufacturing) and the non-academic public. Given the fact that the topic of interest to the charity is a central tenant of Smart Manufacturing and Industry 4.0 research, the Centre was keen to assist.

Solution

Following a discussion with the organisation, a principal investigator within CONFIRM and a post-doctoral researcher consulted with the EPE manager to co-create a workshop based on our expertise which would address the needs of the charity. The main challenge for the group was around GDPR and data management and ensuring the security of their users data. A workshop was developed which addressed these themes and was delivered to the organisation in late 2019.

Following extremely positive feedback from the organisation, we plan to develop the workshop further and offer similar activities to community groups and similar organisations as part of the core EPE programme relating to data analytics research.

Key Benefits

- Using our EPE program to develop the professional capacity of staff of a non-profit using a core element of our research competency

- Increased levels of engagement with the community with the potential of this group to engage in and affect the research process itself (i.e. community engaged action research)

- Develop the skills of our research team in terms of their ability to apply their research in a real world, non-industrial and non-academic setting dispelling the misconception that STEM research is not relevant to the life of the “ordinary person”

- The workshop can be pitched at virtually any audience and so allows for engagement with the Centre despite age, socio-economic background or location thereby enhancing the ability of the EPE programme and the Centre as a whole to have an impact on society

Problem

Accucode AI (Europe) is a provider of 3D printing, scanning and design services for industrial manufacturing including of Electronic Components and Circuit Boards. Quality assurance is of critical importance in electronics related manufacturing processes. However, despite the rapid adoption of Additive Manufacturing by the industry, current 3D printing processes for manufacturing of electronic components and circuit boards remain largely open-loop, with limited real-time monitoring capabilities. While some 3D printing machines offer print bed visualization during builds, they lack automated analysis capability. There is a need for a machine learning based algorithm that is trained to detect anomalies in the 3D printing process of electronic components through evaluation of datasets produced during print runs in real-time.

Solution

CONFIRM researchers at University of Limerick are working with Accucode AI to develop a software library of fundamental electronic components and products, re-designed specifically for the 3D print manufacturing process. A functioning prototype 5G enabled product composed of 3D printed devices and electronic components has been designed. A Machine Learning (ML) inspired anomaly detection engine that is capable of processing data in real-time from 3D electronic component print runs is currently under development. Furthermore, researchers at CONFIRM are working with Accucode to develop new ISI standards in the areas of data formatting and content production, during the 3D printing process of electronic components, to enable real-time feature extraction from datasets.

Key Industry Benefits

- Step change improvements to the 3D printing technologies that currently exists in this space, and will be a game changer for the electronics sector both nationally and internationally.

- The creation and application of new standards driven algorithms will reduce production costs and will have significant use case benefits.

- The Accucode-CONFIRM collaboration will advance Accucode’s knowledge base in the design/automation and optimization of electronics and 3D printing solutions for the electronics manufacturing sector.

Link to national or regional initiatives for digitising industry

The CONFIRM Smart manufacturing Research Centre was established in 2017, as part of a national strategic initiative supported by Science Foundation Ireland (SFI), the Irish national foundation for investment in scientific and engineering research. The foundation of the CONFIRM Smart manufacturing DIH is a key part of the CONFIRM vision to accelerating the adoption of digital technologies and Smart manufacturing innovations among SMEs and MNEs in the Irish manufacturing sector. CONFIRM DIH is aligned with Irelands regional Research and Innovation Strategies for Smart Specialisation (RIS3) which places a strong focus on the key areas of SME support, enhanced competitiveness, and the local delivery of assistance to entrepreneurs and smaller firms via the new local innovation support structures. Ireland’s published RIS3 strategy document provides the national and regional context for Smart Specialisation.

https://dbei.gov.ie/en/Publications/Publication-files/RIS3summary2014.pdf

The CONFIRM DIH will serves as a conduit for investment in research & innovation in Irelands manufacturing sector, raising the profile of CONFIRM research and industrial partners at national and international level, and broadening research and innovation opportunities for CONFIRM partners through collaboration in pan-EU consortia and initiatives. Improving investment in science, technology, and innovation to ensure future economic and social development is an ongoing priority for the Irish Government evident in the allocations for investment in science, technology, and innovation by Government in the current and previous National Development Plans, and Programmes for Government.

Research and Innovation performance information for Ireland is available at: https://rio.jrc.ec.europa.eu/en/country-analysis/Irelan,d

Under Ireland’s RIS3 strategy and Prioritisation of Research, significant progress has been made over the past two decades in building a research ecosystem that in some instances is amongst the best in Europe; in retaining and attracting top level researchers; and in achieving closer synchronisation between research endeavour in Higher Education Institutions (HEIs), Government agencies, and industry. However, to reflect the impact of technological change and the digitisation of manufacturing since 2012, Ireland’s research Priority Areas were recently updated for 2018-2023; https://dbei.gov.ie/en/Publications/Research-Priority-Areas-2018-to-2023.html. In this priority refinement, the Manufacturing Competitiveness priority area has been renamed Advanced and Smart Manufacturing. The CONFIRM DIH is strongly aligned with Ireland’s Advanced and Smart Manufacturing research priority.

The Disruptive Technologies Innovation Fund, launched by the Irish Department of Business, Enterprise and Innovation in 2018, is designed to support research measures related to Digitising Industry. One of four funds in the National Development Plan 2018-2027, it provides a total of €500 million available for co-funded projects involving enterprises and research partners over the current period to 2027. The CONFIRM DIH vision and CONFIRM’s research focus areas of predictive modelling, advanced analytics, robotics, and cyber-physical systems are well aligned with the core innovation themes of this fund namely – ICT, & Manufacturing & Materials which are detailed below-

Industry Academic collaboration, and cross-sectoral clustering within the context of digital manufacturing are core principles at the heart of the CONFIRM DIH. Furthermore, the strategic importance of the DIH “Community of Practise” paradigm in an innovation context is articulated within the Irish Government’s “Making it in Ireland: Manufacturing 2020” policy document.

The CONFIRM Smart Manufacturing Research Centre and DIH are actively engaging with policy makers at national level and have been an important participant and contributor to the new National Strategy for digitising manufacturing which is to be published shortly.

European Initiatives

From a European-level, CONFIRM is also well-aligned with the Digital Europe Programme Focus Areas:

- Supercomputing

- Artificial intelligence

- Cybersecurity and Trust

- Advancing Digital Skills

- Ensuring widespread adoption of digital technologies across industry and wider society

CONFIRM’s research base has knowledge capital, research capabilities and infrastructure to support digital transformation across SME and larger industry. CONFIRM investigators and lead researchers have coordinated and partnered in a wide range of EU-funded projects. Some examples include:

- SMART 4.0– ‘Smart Manufacturing Advanced Research training for Industry 4.0’ that is a EU funded MCSA-Cofund programme to establish and deliver world-class training and research opportunities to post-doctoral fellow in order to increase Europe’s critical mass in the field of smart manufacturing and digital transformations in industry.

- ASAP– ‘Adaptive Security and Privacy’ ERC-Advanced grant awarded research programme aims to radically re-conceptualise software engineering for ubiquitous computing in ways that are cognisant of the changing: user needs; threats to user assets; and relationships between them. http://www9.open.ac.uk/ASAP/

- Productive 4.0– ‘Electronics and ICT as enabler for digital industry 1 and optimized supply chain management covering the entire product lifecycle is an ECSEL (https://www.ecsel.eu/) funded project. https://productive40.eu/