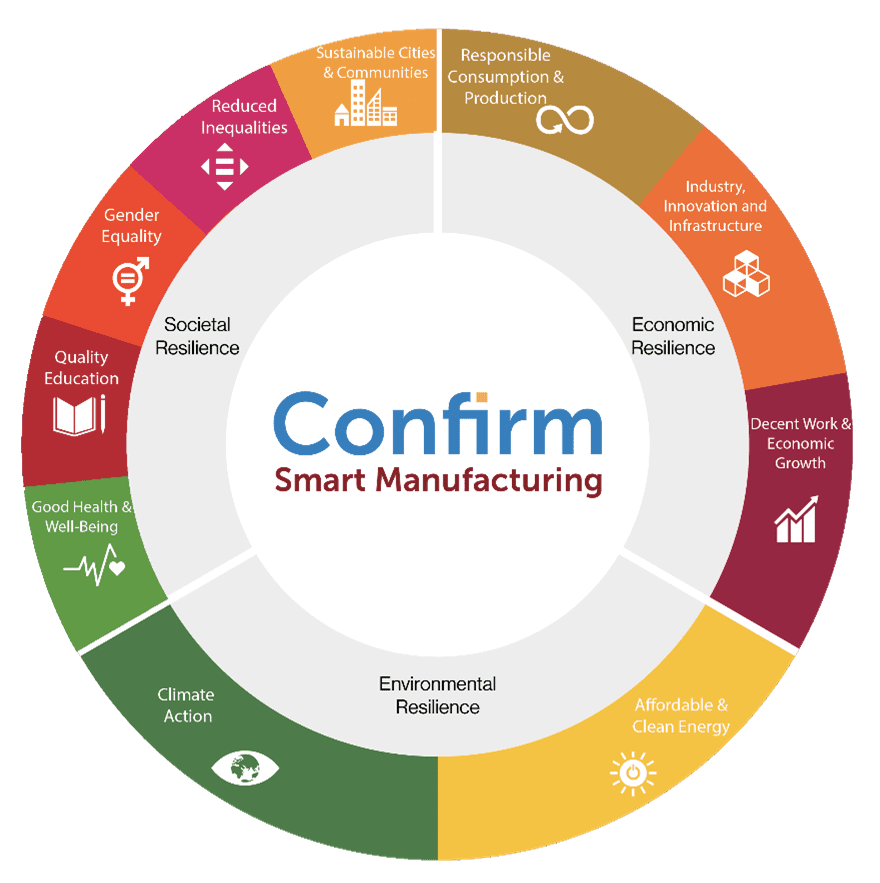

Policymakers, industry, and other key stakeholders are looking at taking a more holistic look at the societal, economic, and environmental impacts of manufacturing and associated challenges. Designing effective approaches that will have positive benefits across each of those aspects are necessary to prepare economies and societies for the future as well as having lasting and positive environmental effects.

This is taking place amid a backdrop of rapid technological advance, which will have huge transformational impacts, and so it is vital to harness this technology for the greater good. It is particularly critical to shape technologies to make industry more sustainable. This must entail sustainability in the fullest sense, covering the economy, environment, and society. In this way, technological advances will feed into environmental advances/improvements.

The most critical trait that has been identified over the last several years by industry and policymakers is that of Resilience, which is taken to have an extensive meaning. Resilience is one of the most significant challenges facing industry and society over the next decade. Global disruptions, natural and manufactured, are leading to mass factory shutdowns, demand surges for essential goods, dwindling natural resources, and shifts in consumer behaviour and modes of work. All these negative impacts are challenging to global value chain flows, with resulting grave consequences for society, businesses, consumers, and to the wider global economy. These disruptions have brought into sharp focus the need for companies to transform their manufacturing operations to be sustainable, highly automated, flexible, and agile. And for workforces to be supported such that they can adapt and respond to market needs and opportunities.

Following extensive consultation and review of national and international strategy documents, CONFIRM has distilled this emerging global picture and identified two Grand Challenges in its expert area of Smart Manufacturing. These Grand Challenges have been carefully conceived and formulated in terms of supporting the UN Sustainable Development Goals (SDGs) and boosting economic development more broadly. The Grand Challenges concern the development of resilient manufacturing systems, and secondly, the creation of a future ready workforce.

CONFIRM Grand Challenges

- Resilient Manufacturing Systems

- Future Ready Workforce

These Grand Challenges will provide the lodestar for all CONFIRM’s research in Smart Manufacturing during its Phase 2 research programme (2023-2029).

Resilient Manufacturing Systems is vital to any industrial ecosystem, especially one that needs to be responsive to threats and severe disruption, and capable of meeting rising environmental and social requirements. For industry to develop such capabilities, it will need to increase the responsiveness, efficiency, and adaptability of its processes, thereby significantly increasing manufacturing performance.

A Future Ready Workforce will involve humans and AI/machines working collaboratively, with digitalisation and automation augmenting workers capabilities and enhancing their roles. It will be necessary to develop the education, skills, knowledge, and facilities to enable the necessary technology diffusion and knowledge absorption capacity and deliver on a vision of digital transformation.

Out of these two Grand Challenges arise significant research questions around production and supply chain resilience, along with how to develop a future ready workforce able to adapt to new industry shifts, and this has formed the strategic backdrop to CONFIRM’s Phase 2 research programme.

To drive impact, CONFIRM’s Phase 2 is adopting a mission orientated research and innovation approach as a problem-solving framework to fuel innovation led growth to address those Grand Challenges.

The five missions that have been identified as areas of focus for CONFIRM Phase 2 are:

- Distributed Making

- Green Supply Chain

- Flexible Manufacturing Cell

- Manufacturing Transition Platform

- Digitally Enabled Work

These five missions are in turn fed by five interwoven key research themes:

- Cognitive Production Systems

- Distributed Supply Chain & Manufacturing Systems

- Secure Manufacturing & Supply Chains

- Human-Machine Collaborative Manufacturing Systems

- Circular Manufacturing & Supply Chain Systems

This approach ensures that, from the outset, all the research themes are strategically aligned, focused, and mutually reinforcing.

Phase 2 Missions (Part 1) _– Grand Challenge of Resilient Manufacturing Systems

The missions that CONFIRM has defined are carefully designed to meet the two identified Grand Challenges of Resilient Manufacturing Systems and Future Ready Workforce. In responding to the challenges, the missions will deliver significant impact and provide clarity that ensures all underlying research themes are strategically aligned and collaborative from the outset. For each of these five missions, CONFIRM will develop exemplar digital-physical mission demonstrators for exploitation to industry, government, public and other stakeholders.

Resilient Manufacturing Systems – Missions x 3

- Distributed Making

- This mission will develop an adaptable, reconfigurable, intelligent, secure, and distributed factory to enable decentralised local production that is closer to the end consumer. This is in turn more sustainable and offers a means by which regions can boost knowledge capital and the integrity of their supply base by localising some core manufacturing capability.

- Green Supply Chain

- This mission involves developing net-zero emissions factories, production systems and logistics, enabling the redesign of end-to-end supply chains such that they are ethical and environmentally friendly, reducing environmental impact and social exploitation.

- Flexible Manufacturing Cell

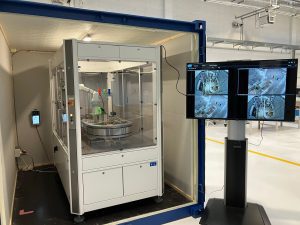

- This mission entails developing a cloud-driven, robotics based, modular, cognitive, reconfigurable manufacturing cell that can easily be reconfigured in response to new production requirements and enable smaller batch sizes. It makes production facilities more adaptable to market changes.

Embedding resilience in manufacturing will entail developing critical infrastructure, building a flexible supply base, and facilitating transparent information flows. The three missions outlined here will support those objectives and feed into realising the Grand Challenge of Resilient Manufacturing Systems.

Phase 2 Missions (Part 2) _– Grand Challenge of Future Ready Workforce

The missions that CONFIRM has defined are carefully designed to meet the two identified Grand Challenges of Resilient Manufacturing Systems and Future Ready Workforce. In responding to the challenges, the missions will deliver significant impact and provide clarity that ensures all underlying research themes are strategically aligned and collaborative from the outset. For each of these five missions, CONFIRM will develop exemplar digital-physical mission demonstrators for exploitation to industry, government, public and other stakeholders.

Future Ready Workforce – Missions x 2

- Manufacturing Transition Platform

- This mission will develop an open platform that leverages physical hubs/labs and digital portals in the transfer of knowledge and skills to support small and medium enterprises and the manufacturing workforce in the adoption of new digital manufacturing technologies.

- Digitally Enabled Work

- This mission involves the creation of a collaborative human-machine workforce through human-centred, AI powered technologies to empower people and teams in the world of work as technology advances and automation replaces mundane and dangerous manual tasks.

Preparing the Future Ready Workforce is about imagining future visions of working life that will be characterised by evolved or entirely new job roles, in factories operating the latest in cyber-physical systems that are also safe and pleasant spaces, conducive to creativity and purposefully designed to allow for ease of collaboration. This human-centred production system, while featuring mobile collaborative robotics that operate alongside the human workers, and a range of complementary wearable technologies, will at the same time emphasise the need for a variety of soft skills, driven by an increase in remote collaboration and the evolution in customer relationships. In many ways, this Grand Challenge is about facilitating more adaptable modes of work in more amenable workspaces for people in a variety of circumstances.

Research Themes feeding into the Missions

The mission orientated approach is aligned to CONFIRM’s resilient manufacturing vision and is underpinned by the CONFIRM Phase 2 research programme, comprising five core research themes.

From the five missions CONFIRM has identified, it has developed five research themes that feed into those missions. These themes form the basis of research programmes that will underpin and achieve the mission objectives.

- Cognitive Production Systems

- This research theme focuses on the challenge of better understanding manufacturing processes in real-time, using sensor data that drives advanced models (e.g., closed-form, statistical, numerical, data, AI, Machine/deep learning) to optimise processes from a productivity and sustainability point of view. Investigation of cognitive production systems starts at the machine-product interface, and then works up through the production system to the full factory, and then into the supply chain. We consider cognition in a full factory and supply chain context, where spatial awareness of humans and machines is required to advance the creation of safe, modular, flexible, and easily reconfigurable future factories.

- Distributed Supply Chain and Manufacturing Systems

- This research is critical to develop future factories and supply chains, where different phases of production will no longer be constrained to one factory or location, but federated so that products can, for example, be finished locally for a local market. Key research topics include future wireless communication and sensing systems between autonomous and reconfigurable manufacturing systems and machines/products, connectivity in inter- and intra-factory contexts and across supply chains, platforms for re-configurable manufacturing processes and supply chains, data models to enable highly distributed manufacturing, and tools to enable analysis and design of future distributed manufacturing and supply chain processes. This will influence the behaviour of transport, logistics, finance, and consumers and will enable new manufacturing business models and platforms to emerge.

- Secure Factory and Supply Chain Systems

- This research theme is critical to enable manufacturing to become more digitalised, sustainable, secure, and resilient, and to compete successfully in an increasingly digitalised world. For the manufacturing sector, there are three interdependent layers that must be protected from cyber threats: (i) the operational technology layer (i.e. the physical machines, products and digital assets in the factory); (ii) the information technology (IT) layer (i.e. all the IT systems that control the factory, including cloud services); and (iii) the supply chain layer (i.e. all the interoperable systems that enable a smoothly functioning manufacturing supply chain base and economy), emphasising that digitalisation is a pre-requisite for achieving secure supply chains.

- Human-Machine Collaborative Manufacturing Systems

- Human-machine collaborative manufacturing systems are critical to the future of work, where we see major research questions emerging with a view to enhancing the attractiveness of manufacturing occupations, as well as promoting the performance, safety, and productivity of workers, through AI and robotic assistance, haptics and AR/VR/XR systems. CONFIRM’s philosophy here is to enhance human performance, rather than replace workers, and so a key research focus will be on user experience and technology adoption from both a technological and human factor viewpoint.

- Circular Manufacturing and Supply Chain Systems

- Research into circularity is critical to realise a sustainable economy, society, and environment. Key research questions concern regenerative systems, energy harvesting in production systems, and product design for life-cycle analysis. Supply chain research challenges include product circularity, re-manufacturing, re-use and recycling, end-of-life protocols, product life-cycle health, and active and passive product identification (AKA product passporting).

Each research theme will involve conducting fundamental platform, industry targeted, and education and public engagement (EPE) research projects that address the Grand Challenges via their contributions to their associated missions. These projects include interdisciplinary collaboration spanning across the research themes.